AN ANNIVERSARY TO CELEBRATE: 100 YEARS OF INNOVATION

Already 100 years since the Etablissements GRANGIER were founded by Emile Grangier, at 20 rue Sainte Marie in Lyon. Discover how in one century a family business has transformed the way of working of many craftsmen and industrialists by inventing and manufacturing innovative materials and equipment.

THE FIRST GENERATION

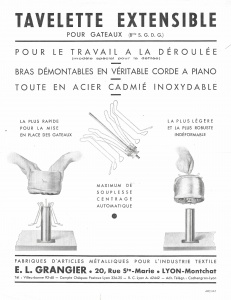

Emile Grangier was an in-house engineer. He had an attraction for the textile trades and it was in this field that he developed his creativity and ingenuity to create metal items and accessories for weaving workshops and looms. His workshop resembled a typical workshop of the time where the manufacturing process was completely integrated from start to finish. Even the tools needed to manufacture the products were designed, tested and machined on site by Emile.

The first patent registered by Emile Grangier was for a device to detect thread breakage on looms: the warp breaker was born! This device saved the weavers a lot of time and the quality of their production was greatly improved. Very quickly, the activity took off around the loom manufacturers and the French weaving workshops.

A FAMILY HISTORY

In 1968, after Emile's death, his son, Hubert Grangier, who wished to keep his father's business, convinced his mother, Simone, not to give it up. Together, they continued to build partnerships with loom manufacturers and weaving mills, while Hubert worked on the creation of new machines for this environment.

Wishing to follow in his father's footsteps, Hubert obtained several CAPs: draughtsman, fitter, turner and miller. This multiple training allowed him to completely master the design and manufacture of Grangier machines.

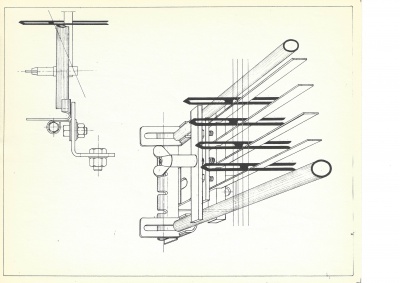

The company began to be known for its inventiveness, and in 1972, two salesmen :

M Tartivel and M Friess, working in the electrical industry, succeeded in convincing Hubert Grangier to manufacture a machine for cutting/punching Din rails (standardised metal profiles for fixing equipment and wiring terminals in boxes, panels and electrical cabinets), as nothing existed on the market.

In a few weeks, after numerous tests in the workshop, the first two prototypes of the "Coup'Din" were created. The two delighted salesmen left with Hubert's invention under their arm, which they took on the task of making known to their customers throughout France. Immediately, they met with complete success, and the Coup'Din equipped a good number of electrical cabinet wiring workshops, and it continues to do so today!

THE INVENTION

Before the invention of the "Coup'Din", panel builders had to clamp the lengths of Din rails in a vice, and use a saw and a drill to cut and drill the rails, then deburr them with a file. With the exponential use of these standardised Din rails at the time, it became very tedious for the cable worker to perform this repetitive and non-value-added task.

Since the creation of the "Coup'Din", panel builders have had a compact device that allows them to drill and cut Din rails quickly. It is efficient, quiet and clean, as there are no more sawing/drilling chips, and its fast, burr-free operation greatly reduces the risk of hand injuries.

CHANGING TIMES

In the 1980s, the textile industry in France underwent major changes. French weaving mills began to close one after the other, driven by the inexorable relocation to low-cost countries. The company had to deal with a decline in its customers throughout France: weavers and loom manufacturers were closing down one after the other.

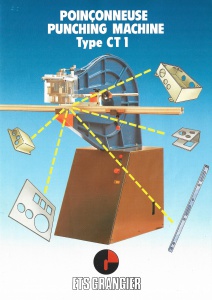

Nevertheless, thanks to the great success of the first "Coup'Din", Etablissements Grangier made a change of direction and shifted their activity towards the panel maker, cable maker and electrician trades.

THE THIRD GENERATION

In 1992, François Grangier took over from his father Hubert. He is the third generation to work in the workshop and still at the same address. Before that, François trained and obtained a technical BAC in mechanical engineering and then a BTS in technical sales.

François is imbued with family values such as rigour, a taste for work well done and the desire to get to the bottom of things. His father having awakened in him a curiosity and a taste for finding simple solutions in the field of mechanics, he perpetuates the family tradition by creating new machines inspired by his numerous trips to meet customers.

In 1999, he designed the first "CT2" door and box punching machines. He also created the "Cisabarre", for cutting, punching and bending copper bars. These machines are used in the manufacture of electrical cabinets. The range became particularly extensive.

As with the design of the first "Coup'Din", these machines were created in response to customer demand and correspond perfectly to the needs of the market.

SINCE THE YEAR 2000

With his feet firmly planted in the present day, François realised that the digital era was the gateway to new markets, particularly for exports. He therefore decided to create his first website in 2000, on which he presented his complete range of products for the French, European and world markets.

In order to gain in reactivity and in manufacturing quality, Ets Grangier acquired a machining centre for the manufacturing workshop in 2001, and then quickly a digital lathe. These machines allow the manufacture of punches, dies and numerous components in a reduced time.

In 2012, to facilitate the rapid design of special tools and machines, the company invested in its first 3D design software. This innovative equipment allows the company to evolve with the market and speed up the design and manufacturing processes.

In the meantime, a complete range of dies for electricians has been added to the numerous product references marketed by Ets Grangier.

TODAY

Etablissements Grangier markets a wide range of equipment and machines for panel builders and cable makers. The three innovations that were the "Coup'Din", the CT2 (punching machine for doors and boxes) as well as the "Cisabarre" (punching and bending shears for copper bars) are still very successful today. These are the brand's flagship products and are sold in France, Europe and all over the world, thanks to numerous commercial partnerships.