Serving the panel builder's trade: how does GRANGIER improve the productivity of electrical professionals?

The commissioning of electrical equipment is the culmination of a long process of study, assembly and testing.

Electrical installations require increasingly complex multi-technical integrations; electrical, electronic, hydraulic, pneumatic or mechanical components as well as design and functionality are inseparable.

It is also important to consider the different materials used in the manufacture of the equipment, ranging from copper, steel, stainless steel, aluminum or plastic materials.

Each installation, whether it is a switchboard, a box, an electrical cabinet or a series of electrical units, is customised so that each of the elements contained in the equipment finds the best place.

To this end, GRANGIER SAS develops and builds standard and customised machines and solutions for electrical construction.

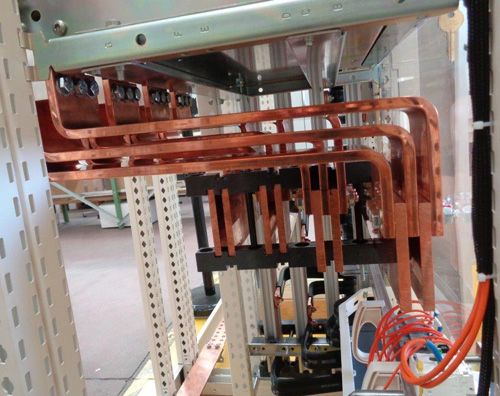

Interior of an electrical cabinet at the beginning of assembly, with trunking and Din rails installed, using Coup'goulotte and Coup'Din equipment

The machines and equipment used for installations inside electrical cabinets, panels and boxes

The cable installer installs and connects the many elements that make up an electrical cabinet, control panel or box according to the wiring diagram. In order to make this installation easier, to comply with the standards in force and to reduce working time, several machines and tools are used:

- Coup'Din" Din rail punching shears

The cutting and punching of Din rails can be carried out with the Coup'Din GH3 machine or the ALG combination. These standardised metal profiles are used to attach electrical control and safety devices such as circuit breakers, relays, timers, wiring terminals, etc.

Whether manual, electric or pneumatic, the punching shears make precise cuts and punches (to the millimeter), clean without burrs.

Several combinations are possible depending on the machine (punching machine or shears only or both at the same time) which makes the operator's work easier. Blades, punches and dies can be adapted to all forms of Din Rails.

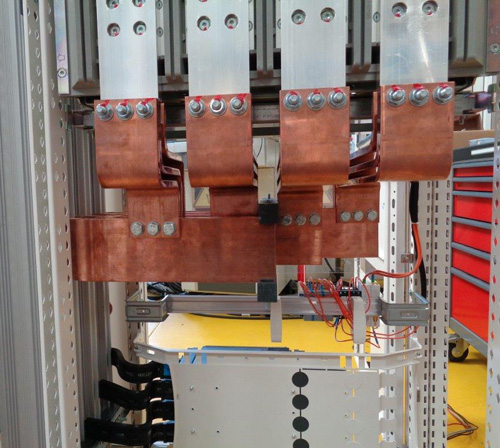

Cabinet with LV panel and circuit breakers, 120x10 cut, bent and punched busbars with Cisabarre CM1 and Folder PH1 machines

The Coup'Goulottes CG125 manual shears are used to cut plastic cable ducts, which contain wires and cables, making it easy to organise and protect the wiring.

The Coup'Goulottes CG125 requires very little effort. The power developed by its geared mechanism allows for stress-free work. The shears cut cable ducts, covers and plastic caps up to 125 mm wide with great precision and without any defects or burrs on the edges.

Compact and space-saving, it can be used in the workshop, on a fixed or mobile workbench for serial cutting or at the foot of the cabinet. The large engraved support rule and its stop ensure a clean and precise cut.

-

Bending machines, punching machines, shears for working with copper bars

The Cisabarre CM1 and the PH1 bending machine make it easy to cut, punch and bend copper bars mounted inside electrical cabinets for the distribution of high currents.

Several types of machines, combined or not, have been developed to meet the needs of the cable workshop, whether it is a craft or an industrial one. Thus, the Cisabarre CM1 combined machines will allow a triple function of cutting + punching + bending of copper bars. The use of a single machine will thus be possible to produce a switchboard with copper bars.

To complete or multiply the independent workstations, the PH1 hydraulic bending machines meet the unique need of bending copper bars. They allow series work for repetitive bending with high precision. Equipped with articulated arms for holding the bars and engraving the main angles on the bending plate, they ensure easy and quick work for the operator.

Machinery and equipment useful for installations on the enclosure of electrical cabinets, switchboards and enclosures

-

CT2 door and cabinet punching machines

This range of punching machines has been developed to meet the need to punch doors, panels and cabinets in the workshop. These punching machines can be manual or hydraulic.

The CT2 manual or hydraulic punching machines allow the rapid drilling of doors and panels of electrical cabinets and boxes. This makes it much easier to quickly fit sight glasses, buttons and control devices, as well as cable glands for the passage and fixing of cables.

-

Hole saws, workpiece cutters and portable pumps

GRANGIER SAS also distributes or manufactures hole saws, standard and non-standard steel cutters, stainless steel cutters, in various shapes (round, square, rectangular, oblong...) and in many dimensions and diameters. The dies can be ordered individually or in a box.

For the actuation of the dies GRANGIER SAS offers spanner screws, hand pumps, foot pumps or battery operated electro-hydraulic pumps.

The punches, which consist of a punch and a die, are mobile and can be used to drill holes in electrical cabinets and boxes on site. From a hole made with a drill, into which a screw or a traction pin is passed, onto which the punch and die are screwed, the places where the indicators, buttons and control and command devices will be placed are drilled. A spanner or a portable hydraulic pump will be used for a clamping and punching action of the sheet metal placed between the punch and the die.

Electrical cabinet ready to be delivered with control lights, rotary switches, measuring devices and fan grills installed on the front.

This work was carried out with the CT2 punching machine and/or punching dies